지불 유형:L/C,T/T,D/P,Paypal

인 코텀:FOB,CFR,CIF,EXW,FCA,DDP,DDU,CPT,CIP

최소 주문량:100 Kilogram

수송:Ocean,Land,Air,Express

포트:Shanghai,Qingdao,Shenzhen

$1.9-99 /Kilogram

모형: HP750T

상표: HP 플레이트, HP 용접

표준: AiSi, ASTM, bs, 소음, GB, JIS

원산지: 중국

종: 강판

생산 과정: 냉간 압연

표면 처리: 코팅

신청: 플랜지 플레이트

특수강: 내마모성 강철, 고강도 강판

공차: ± 1 %

범주: 냉연 강판, 용융 아연 도금 강판, 저 합금 플레이트, 컬러 코팅 강판, 열연 강판, 강판

처리 서비스: 굽힘, 용접, Decoiling, 절단, 펀칭

Standard Thickness 3: 9on8, 12on8, 15on10,17on12, 20on12, 25on10

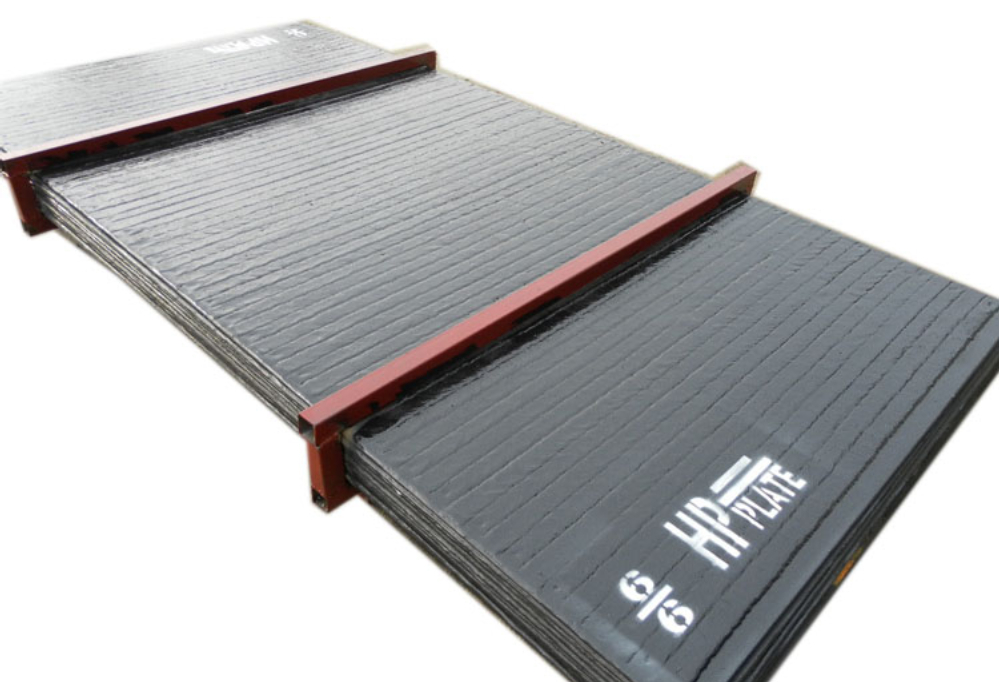

Standard Thickness 1: 3on5, 4on6, 6on6, 7on8, 8on8, 9on10, 10o

Standard Size 1: 3.9' X 4.8' Or 1200 X 2400mm

Standard Size 2: 7.2' X 9.9' Or 2200 X 3000mm

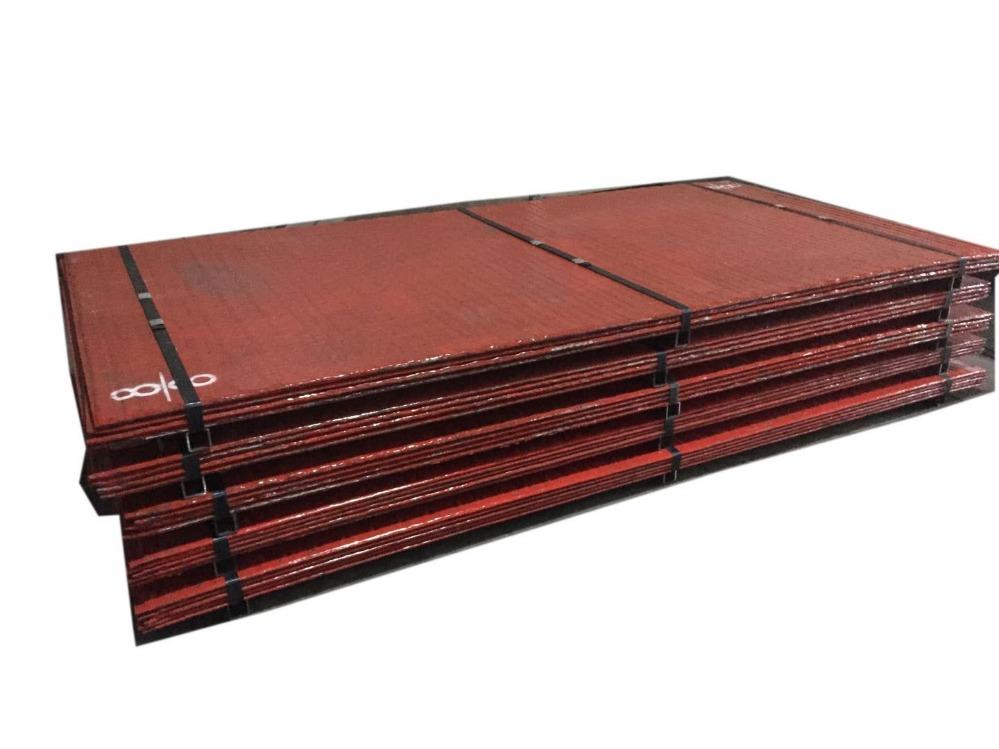

포장: 스틸 프레임 및 스틸 벨트 고정

생산력: 500 tons per year

수송: Ocean,Land,Air,Express

원산지: 중국

지원에 대한 지원: 50,000㎡ wear plate per year

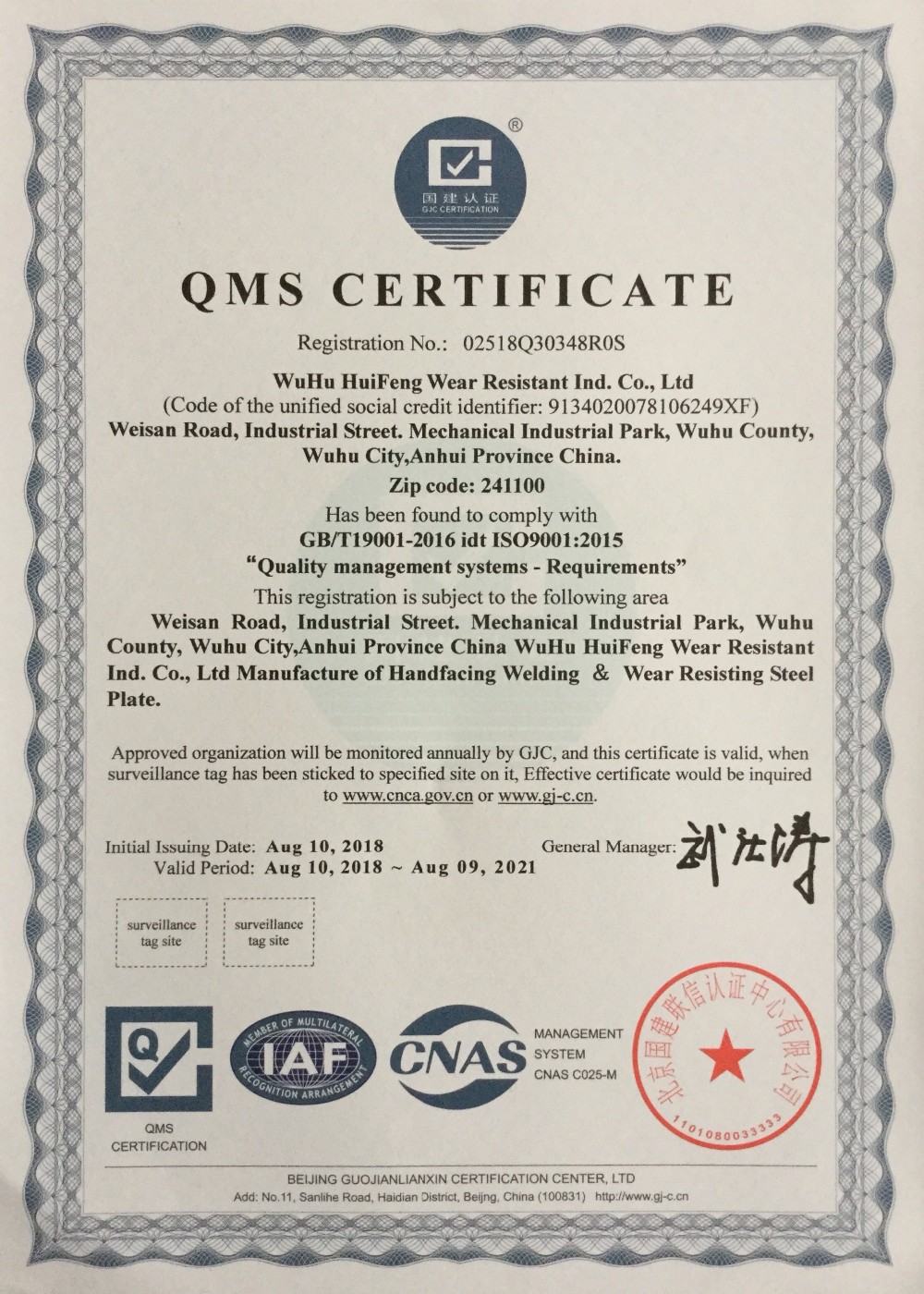

인증 : ISO9001: 2015

HS 코드: 72109000000

포트: Shanghai,Qingdao,Shenzhen

지불 유형: L/C,T/T,D/P,Paypal

인 코텀: FOB,CFR,CIF,EXW,FCA,DDP,DDU,CPT,CIP

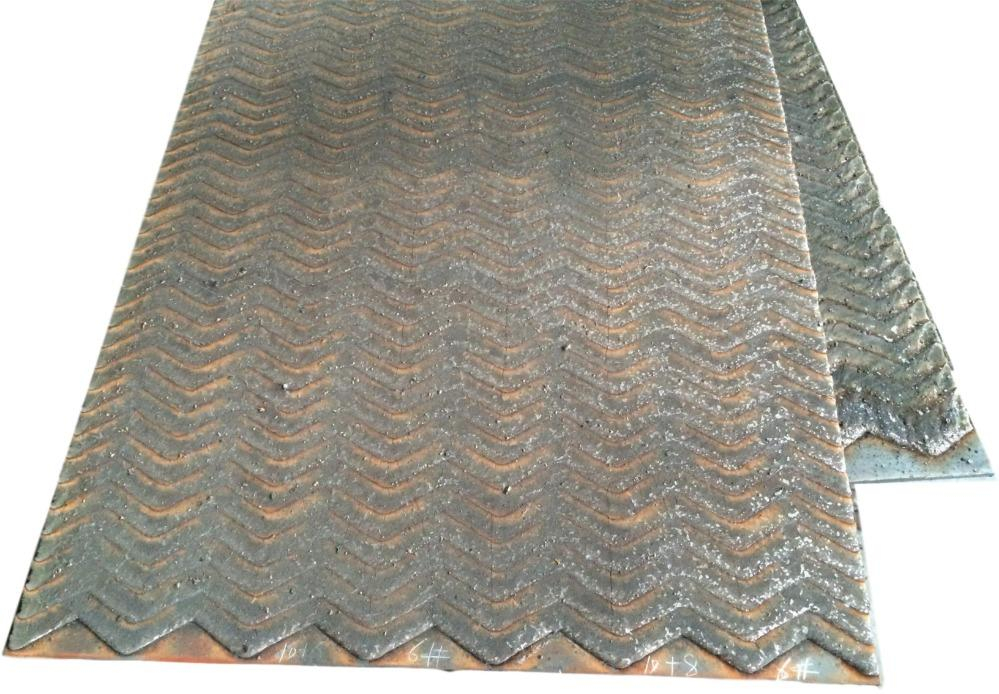

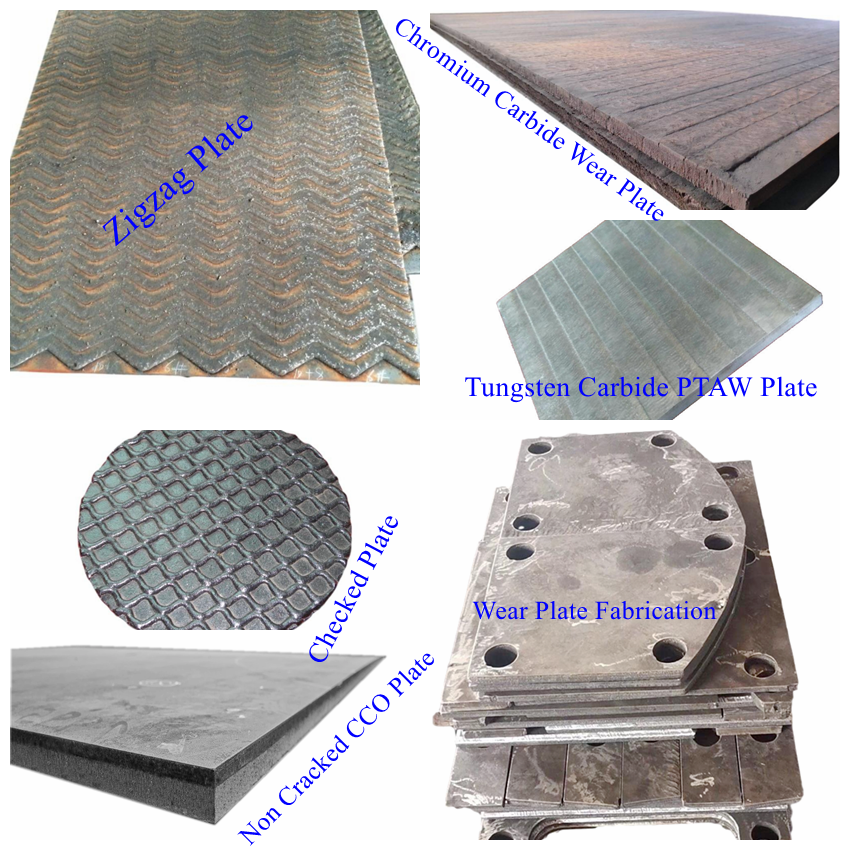

Tungsten Carbide Wear Plate is made by Plasma Transfer Welding process.

PTA is a true welding process, with deposits forming a metallurgical bond with the base metal. The dilution level of Tungsten Carbide Welded Wear Plate by Plasma Transfer Welding is very close to those obtained by using the oxy-acetylene process.

Overlaying Wear Plate is with hardfacing overlay from 2.0 mm up to 30 mm are easily achievable, though most common are the 3mm to 12 mm thickness range. Backing plate can be any weldable steel suited for the application.

This grade material is widely applied to cement industry as Cement Vertical Mill Wear Plate

Quick View On P roduct

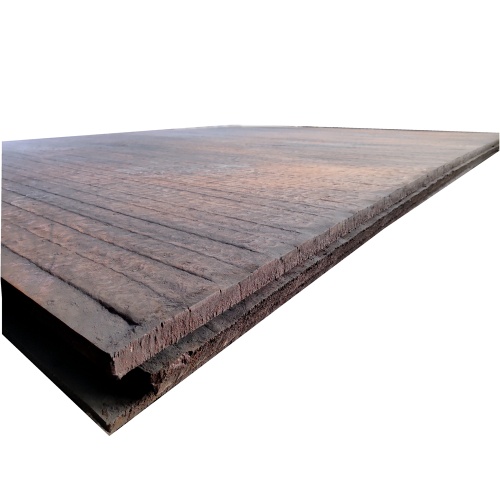

1. Product Name: HP Non Cracked Overlay Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

3. Standard Size: 1200*2400mm; 1000*3000mm or Customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

6. Applications: Cement Industry , Steel Mill, Mining Site, Coal Mine, Chemical Industry, Power Generation & Others

7. Certification: ISO9001, SGS, CTI, ROHS

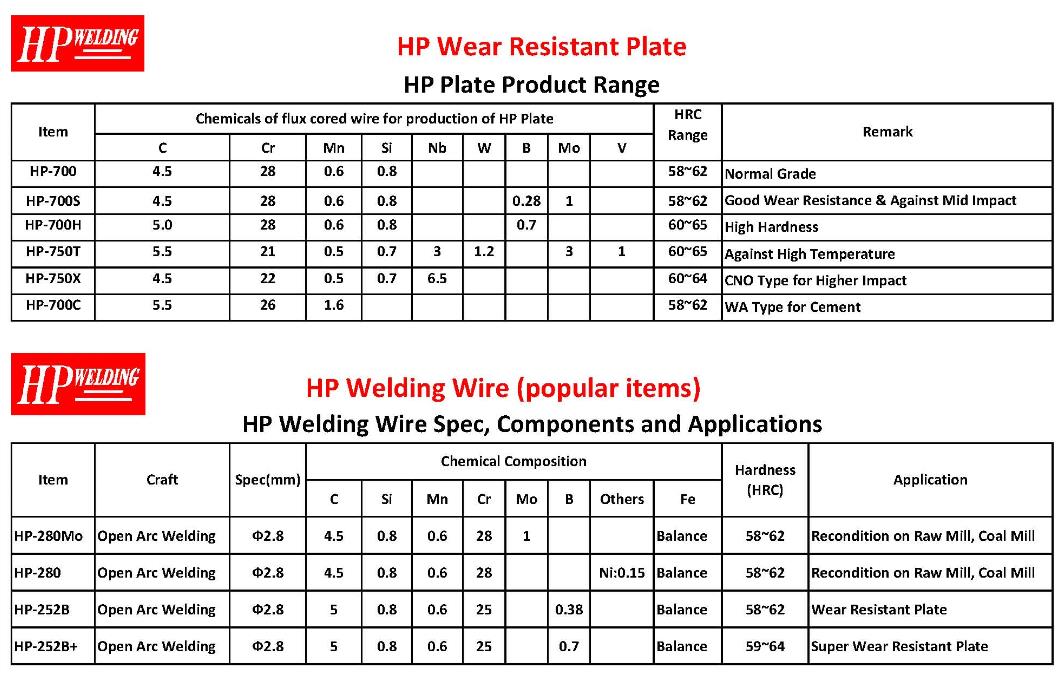

Standard Specifications of HP Wear Plate :

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

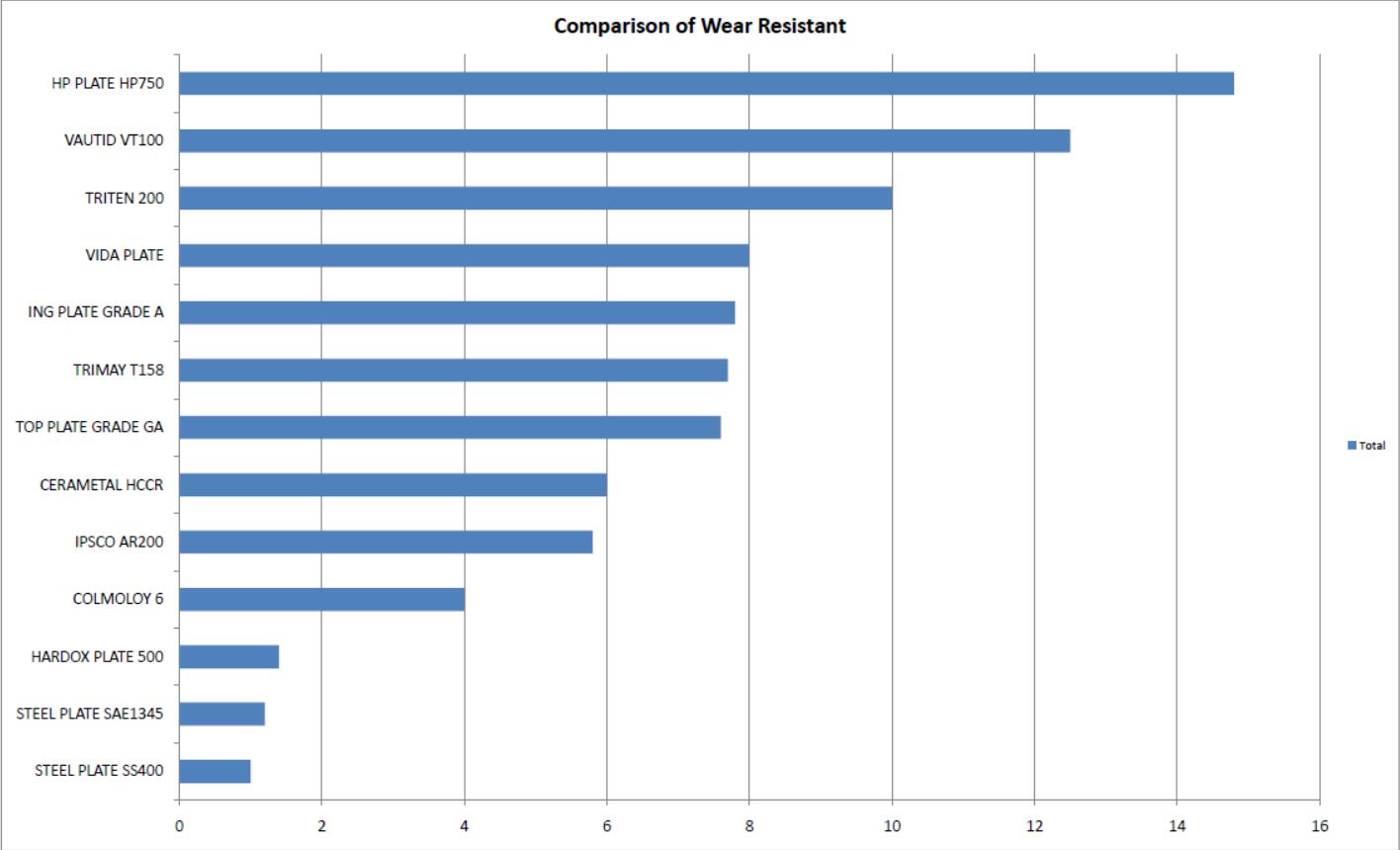

Anti-abrasion Comparison_HP Plate vs Other Plate

회사 정보

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

답변: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.