모형: HP-RL

상표: HP 플레이트

원산지: 중국

처리 서비스: 조형, 절단

Specified Size: Make To Order

포장: 스틸 프레임 또는 우드 케이스

생산력: 500 Ton per year

수송: Ocean,Land,Air,Express,Others

원산지: 중국

지원에 대한 지원: 500 tons per year

인증 : ISO9001: 2015

HS 코드: 4016999090

포트: Tianjin,Shanghai,Qingdao

지불 유형: L/C,T/T,D/P,Paypal,Others

인 코텀: FOB,CFR,CIF,EXW,FCA,FAS,DAF,DES,CPT,CIP,DEQ,DDP,DDU

우리 HUIFENG 내마모성 산업 그룹은 볼 밀의 우수한 내마모성 재료로 최고 품질의 내마모성 고무 라이너 및 볼 밀 예비 부품을 제공하여 30년 이상 고객에게 마모 솔루션을 제공하기 위해 최선을 다하고 있습니다.

Rubber Liner는 그리드형, 오버플로형, 다중창고형 볼밀에 사용됩니다. Abrasion Resistant Rubber Liner는 주로 습식 연삭 공정에 적용되며, 현재는 엄격한 금속 불순물(철)이 필요한 건식 연삭도 적용되고 있습니다. 고무 라이너 플레이트, 시멘트 볼 밀용 쉘 리프터 바 고무 라이너, 볼 밀 예비 부품은 장비에 대한 최상의 보호를 위해 공급할 수 있습니다.

고무 제품 의 주요 사양:

| Performance Index |

Unit |

Standard |

|

Tensile strength |

Mpa |

17 |

|

Elongation |

% |

420 |

|

Permanent Deformation |

% |

10 |

|

300% Tensile Strength |

Mpa |

11 |

|

Impact Elasticity |

% |

45 |

|

Wear Reduction |

cm³/1.61km |

0.15 |

|

Shore (a) Hardness |

65±5 |

|

|

Aging Coefficient (70℃*48h) |

0.8 |

Ball Mill Liner components:

Our ball mill liners solutions can be fitted with lifter bars, shell plates and head plates. We utilise Hardox wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

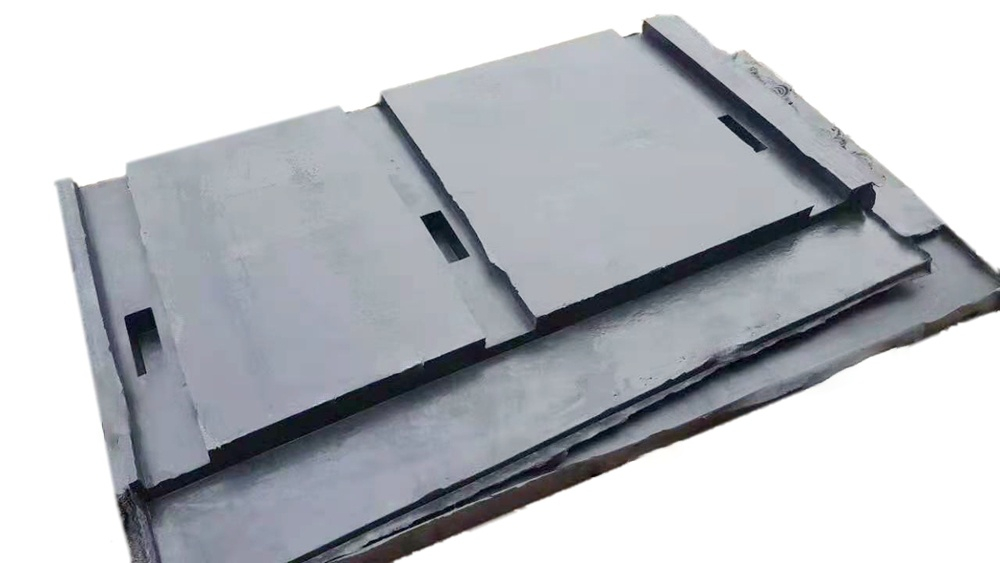

Shell Plates

Shell plate thickness can vary, which helps both in balancing mill capacity as well as extending ball mill liner life. For arduous milling applications, or where drilling patterns produce shell plates that are too wide, thus exposed to high wear, shell plates with Hardox strips can be utilised.

Lifter Bars

Available in a range of profiles and dimensions, lifter bars increase the efficiency of the milling operation by maximising the agitation of the ore. The impact and abrasion resistance of these bars is maximised by Hardox steel along the leadings edges of these components. With a high-quality attachment system, lifter bars are easy to install to the ball mill liner.

Head Plates

We custom-design head plates according to each ball mill to ensure maximum performance and lifespan. Most commonly, our head plates are built from high-quality, specially-formulated rubber. In arduous ball mill applications, Hardox strips can be fitted to the head plates to increase their operational life.

Grate Plates

Grate plates are available in a range of aperture sizes and configurations. Internal frames are designed for different mill loads, and it is possible to use semi-overflow designs in order to control the pulp level in the mill. Different options for extending plate life exist as required by your application, such as built-in lifter bars.

Pulp Lifters

Manufactured with a rubber-lined fabricated steel base, our pulp lifters use high-quality designs that ensure a correct volumetric flow of the pulp. Rubber wear plates designed to be bolted onto the high-wear areas of the ball mill liner improve the performance life of your mill.

Central Cones

These components assist in the controlled discharge of the material, maintaining mill capacity across the operation. Cones are provided in segments, which are then assembled inside the mill. This enables easier handling and manageability.

Trunnion and Bell Mouth Liners

Manufactured with a fabricated steel base that is then rubber lined. Loose steel-reinforced rubber liners are also used in larger trunnions.

Filling and Support Segments

Extend the wear liner to the corners of your ball mill and scrubber, enabling a clean, smooth lining across the ball mill liner.

Key Specifications Of Rubber Product:

Unit

Standard

Tensile strength

Mpa

17

Elongation

%

420

Permanent Deformation

%

10

300% Tensile Strength

Mpa

11

Impact Elasticity

%

45

Wear Reduction

cm³/1.61km

0.15

Shore (a) Hardness

65±5

Aging Coefficient (70℃*48h)

0.8

Packing & Delivery

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 4 weeks after order confirmation or to discuss

Company Information

We are specialized in designing and manufacturing wear resistant products including anti-abrasion rubber lining, polyurethane lining, wear resistant steel products, ceramic liner, conveyor accessories, etc. Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

HP Wear Solution Products Show Case:

HP Factory Laboratory

Performance Index

Q1 : 사용자 정의를 사용할 수 있습니까?

A : 귀하의 요청에 따라 사용자 정의를 지원합니다.

Q2 : 배송 시간은 얼마나 걸립니까?

A : 3 ~ 4 주. 우리는 긴급한 주문이 필요한 주요 원료 재고를 가지고 있으며, 필요할 때 우선 순위가 부여됩니다.

Q3 : 공장을 방문 할 수 있습니까?

A : 그렇습니다. 우리를 방문해 주시기 바랍니다. 가능한 경우 여정을 공유하십시오.

Q4 : 제품의 품질 관리는 무엇입니까?

A : 배달 전에 모든 제품이 엄격하게 검사됩니다.

Q5 : 샘플이 무료입니까?

A : 예, 무료 샘플을 사용할 수 있거나 토론 할 수 있습니다.

Q6 : 구매 주문을 진행하려면 어떤 정보가 필요합니까?

A : 기술 도면이 자세한 내용으로 제공되면 우리에게 큰 도움이 될 것입니다.